Airfix solves the bomber builder’s biggest headaches with brilliant engineering—from anti-tail-sitting ballast chambers to pin-perfect gear mounting that actually strengthens your model

- Kit: A09010 // Scale: 1/72

- Manufacturer: Airfix

- Pros: Ingenious weight distribution system; exceptional parts breakdown; pin-and-socket gear mounting; comprehensive interior

- Cons: Interior work remains hidden after assembly

- Details: Injection-molded plastic (gray, clear); 278 parts; decals

The Consolidated B-24 Liberator’s production numbers speak volumes—18,500 units rolled off assembly lines, securing its place as history’s most-produced bomber. This workhorse featured Consolidated Aircraft’s distinctive high aspect-ratio Davis wing, an aerodynamic marvel that delivered superior cruise speeds and exceptional range. These characteristics proved invaluable across the Pacific’s vast distances and during Atlantic anti-submarine patrols.

Despite its historical significance, the Liberator has languished in the shadow of its contemporary, the B-17, particularly in scale modeling circles. Hasegawa’s offering, now nearly two decades old, stood alone until Airfix delivered this remarkable 1/72 scale kit. Inside the box, you’ll discover engineering solutions that demonstrate why this release was worth the extended wait. The 278 precisely tooled components showcase crisp recessed panel lines and surface detail that meets modern standards. Strategic parts breakdown and supplemental components signal Airfix’s broader ambitions—indeed, they’ve already confirmed a D variant arriving in 2025. Two olive-over-gray marking options come courtesy of Cartograf, while the instruction manual presents assembly sequences through clear illustrations with comprehensive paint references.

Engineering Excellence in the Office

The flight deck represents competent design rather than extraordinary detail, though what Airfix provides proves entirely adequate given visibility constraints. The instrument panel relies on decal representation rather than raised detail—a practical choice for this scale. Yet the designers didn’t stop at basics. Sidewall components, ammunition storage, and bombsight equipment add layers of authenticity.

Here’s where Airfix’s engineering prowess truly shines: they’ve incorporated a dedicated weight chamber beneath the radio operator’s position, designed to accommodate 30 grams of ballast. The instructions note additional weight can be positioned behind the instrument panel. This forethought eliminates the tail-sitting plague that affects many bomber models, demonstrating real understanding of modeler needs. Component fit throughout proves exceptional, with parts clicking together positively.

Hidden Complexity

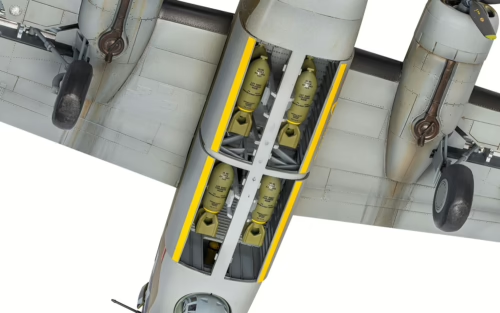

The interior extends from bombardier position through the tail gunner’s station, featuring remarkable completeness. Structural ribbing, floor panels, walkways, ammo storage, and oxygen systems—every element receives attention. The cruel reality? Only the bomb bay remains visible after assembly.

Practical building considerations led me to delay bomb bay installation until final assembly, providing a convenient handhold during painting operations. Similarly, the waist armament benefits from late installation, as the instructions wisely suggest. The ammunition feeds for these positions proved problematic in alignment, ultimately leading to their omission. Waist gunner windows offer closed positioning as an alternative. The fuselage sections united flawlessly, with the forward section integrating seamlessly.

Structural Innovation

Structural Innovation

Builders must select appropriate vertical stabilizer components from two provided sets—attention to instructions prevents errors here. Wing assemblies incorporate well-appointed main gear bays, while flap positioning remains adjustable between deployed and retracted configurations. Ailerons stay fixed. Engine cowlings offer open or closed flap options, though the powerplants themselves deliver merely adequate representation.

During test assembly, the model exhibited tail-heavy tendencies despite installed ballast. My solution involved bonding paired half-inch nuts within each engine nacelle—likely excessive, but effective.

The landing gear mounting showcases genuine innovation. Airfix engineers incorporated a small locating pin on each main strut base that engages a corresponding depression in the tire crown. This seemingly minor detail serves multiple purposes: ensuring correct tire orientation while the molded-in weight effect simultaneously adjusts strut compression. The design theoretically strengthens the entire assembly—time will reveal whether it withstands the considerable ballast load. Note the directional hub installation, as taper exists on one side only.

Turret Precision

Final construction stages address the various defensive positions. Airfix deserves recognition for their approach here—strategic parts separation places all seam lines along natural panel breaks, eliminating visible joint lines. The remaining transparencies installed smoothly, with Eduard’s masking set (CX667) proving invaluable for the numerous window frames.

Finish and Markings

Model Master olive drab and neutral gray formed the base colors. Panel definition came through carefully applied Tamiya Smoke washes, while Model Master Faded Olive provided highlight variation. Cartograf’s decals performed without issue, settling properly over surface details.

Assessment

Assessment

Each iteration demonstrates Airfix’s commitment to advancing their craft. The hours invested in this Liberator—and there were many—proved consistently rewarding. Detail levels, component fit, and design intelligence all reach exceptional standards. Dimensional accuracy matches published references precisely, while the completed model simply commands attention.

The engineering solutions throughout this kit reveal deep consideration for the building experience. From the ballast compartments that prevent embarrassing display issues to the gear mounting system that strengthens while it aligns, these aren’t just parts in a box—they’re carefully orchestrated components designed to work together. The irony of the invisible interior remains, but even this speaks to Airfix’s commitment to completeness over compromise.

For modelers seeking a bomber addition, this Liberator demands serious consideration. The combination of thoughtful engineering, comprehensive detail, and reasonable pricing creates compelling value. While assembly requires patience and experience—particularly with weight distribution and alignment—the sophistication of Airfix’s design minimizes frustration and maximizes satisfaction.

This isn’t merely an update to an aging subject; it’s a masterclass in modern kit engineering. The B-24H demonstrates how contemporary tooling technology, combined with genuine understanding of modeler needs, produces kits that build better and display prouder than their predecessors. Consider this the new benchmark for 1/72 scale multi-engine aircraft.

Key Takeaways

- Engineering breakthrough: Built-in ballast compartment and pin-socket gear system solve common bomber kit problems while strengthening the finished model

- First major update in 20 years: Airfix’s B-24H surpasses Hasegawa’s aging kit with 278 crisply molded parts and modern surface detail

- Hidden detail paradox: Fully detailed interior from nose to tail remains invisible after assembly—only bomb bay shows

- Superior value at $67.99: Thoughtful design, flawless fit, and Cartograf decals deliver exceptional quality for the price point

- Future-proof investment: Extra parts and announced D variant signal expanding B-24 family lineup