The British engine manufacturer expects certification within weeks for its new High Pressure Turbine blade technology that will significantly extend maintenance intervals for Boeing 787 Dreamliner engines.

Rolls-Royce announced Thursday a major breakthrough in its Trent 1000 engine technology that will double the time between required maintenance for Boeing 787 Dreamliners, with certification expected in the coming weeks.

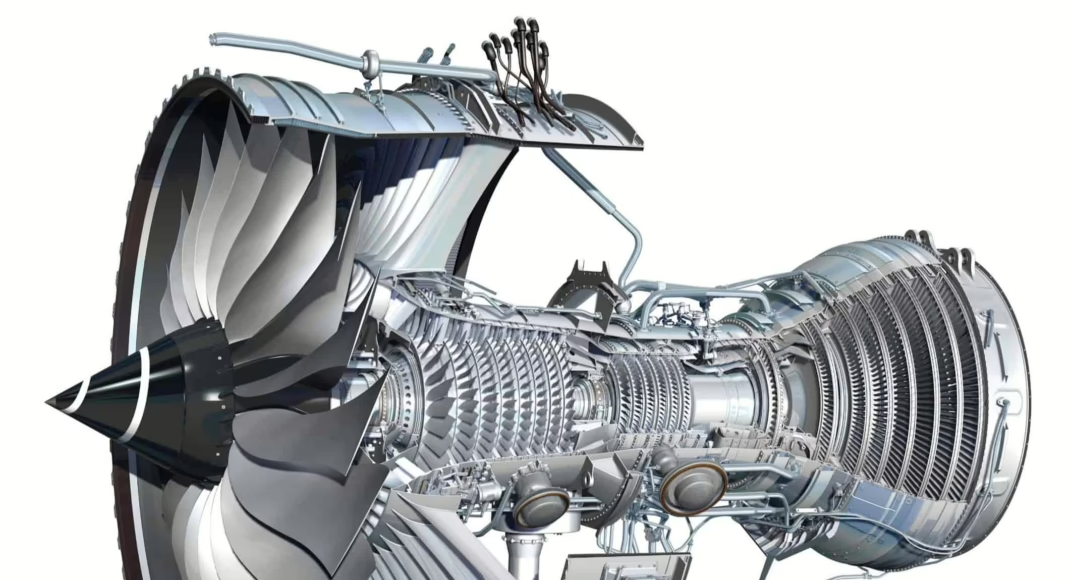

The company’s new High Pressure Turbine (HPT) blade, which forms part of a broader Durability Enhancement package, addresses long-standing durability issues that have affected airlines operating the popular widebody aircraft.

Having “pushed the engine beyond the certification requirements” regarding the new blades, Rolls-Royce expects certification for the technology to be imminent.

The upgraded blade technology has already proven successful on the Trent 7000 engines powering Airbus A330neo aircraft. After more than two years of operation, data from those engines confirms the blade’s ability to more than double time-on-wing performance, according to Rolls-Royce.

Strong Financial Performance Supports Innovation

The engine manufacturer reported a strong start to 2025, maintaining its guidance of £2.7-2.9 billion ($3.4-3.7 billion) in underlying operating profit and free cash flow for the year.

“We have had a strong start to the year, with all divisions performing well,” the company stated. “Despite the uncertainties associated with tariffs and continued supply chain challenges, our 2025 guidance of £2.7 – £2.9 billion of underlying operating profit and £2.7 – £2.9 billion of free cash flow remains unchanged. Year-on-year improvements in profit and cash flow are largely driven by our actions and strategic initiatives. Demand for our products and services also remains strong across the Group.”

Recent developments have included other certification milestones in both commercial and private aviation sectors, with time-on-wing and fuel consumption being among the most critical areas of interest as the company plans its next steps.

Advanced Cooling Technology Drives Performance

The breakthrough centers on improved cooling performance within the HPT blade, which Rolls-Royce engineers achieved through sophisticated thermal modeling and analysis of in-service data from the company’s advanced engine health monitoring system.

“By improving the cooling performance of the blade, we have more than doubled the blade life,” Rolls-Royce explained, noting that enhanced blade life directly translates to increased time-on-wing for the entire engine.

The company has utilized in-service data from its advanced engine health monitoring system and sophisticated thermal modeling to identify how the efficiency of the blades’ cooling system can be improved.

Time-on-wing refers to the duration an engine operates between installation and removal for maintenance, a critical metric for airlines managing operational costs and aircraft availability.

Wider Implications for the Trent Family

The Trent 1000 powers Boeing’s 787 Dreamliner family and is part of Rolls-Royce’s broader Trent engine portfolio, which includes:

- Trent 500 for Airbus A340

- Trent 700 for Airbus A330

- Trent 800 for Boeing 777

- Trent 900 for Airbus A380

- Trent 7000 for Airbus A330neo

- Trent XWB for Airbus A350

The HPT blade technology transfer from the Trent 7000 to the Trent 1000 program demonstrates Rolls-Royce’s ability to leverage improvements across its engine family, potentially benefiting operators of various aircraft types.

The Durability Enhancement package also addresses emissions reduction, aligning with the aviation industry’s increasing focus on environmental performance alongside operational efficiency.

Key Takeaways

- Rolls-Royce’s new HPT blade will double time-on-wing for Trent 1000 engines powering Boeing 787s.

- Certification expected within weeks after exceeding testing requirements.

- Technology already proven on Trent 7000 engines for Airbus A330neo.

- Company maintains strong 2025 financial guidance despite supply chain challenges.

- Improved cooling performance is the key innovation behind extended blade life.