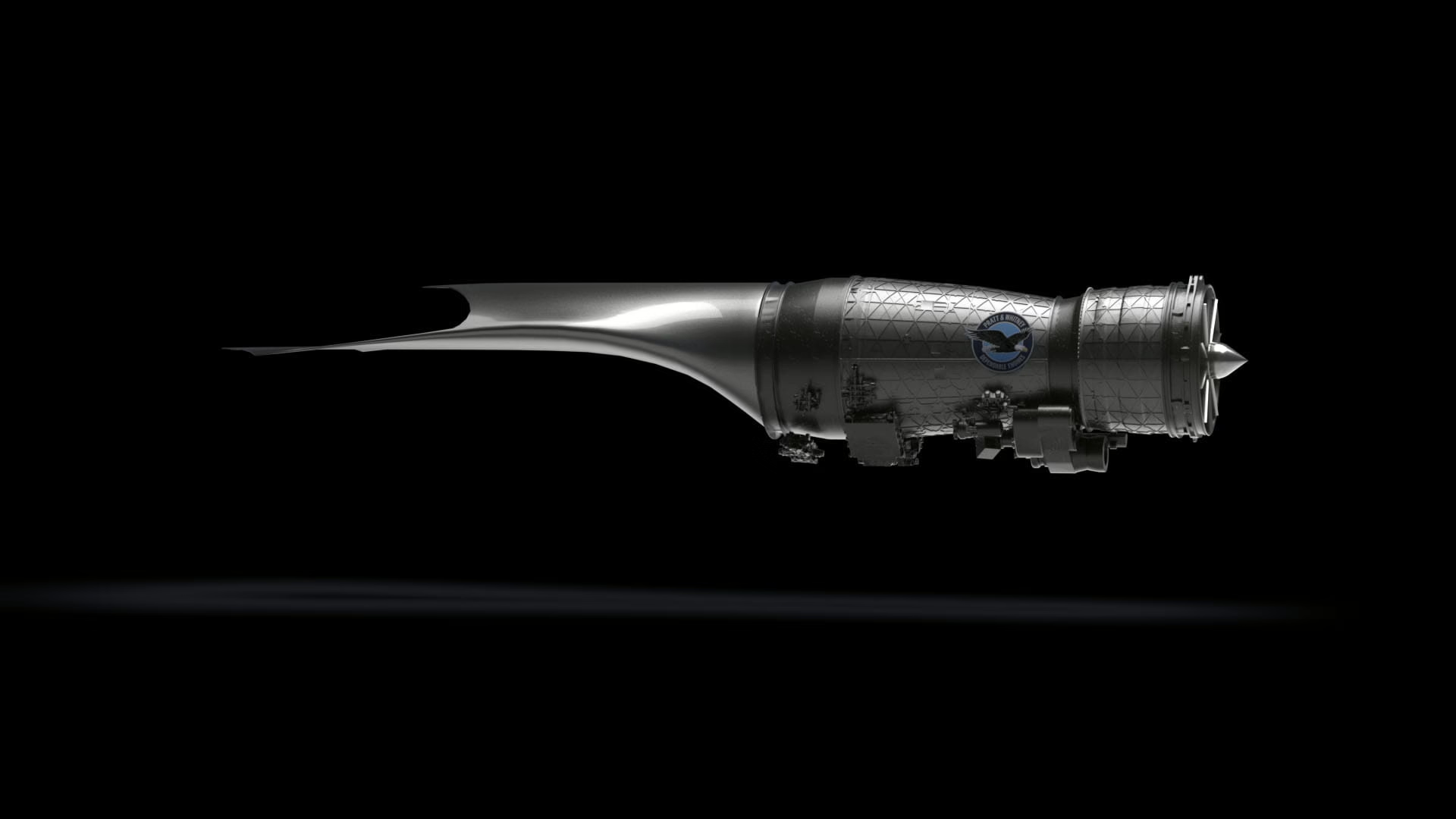

Engine maker assembles XA103 adaptive turbofan in race with GE Aerospace to power future air superiority fighters.

Pratt & Whitney has launched assembly of a prototype engine designed to power the Air Force’s next generation of fighter aircraft, marking a significant step forward in the Pentagon’s push to develop sixth-generation combat capabilities.

The RTX subsidiary started building the XA103 prototype in recent months under the Air Force’s Next Generation Adaptive Propulsion program, which aims to deliver advanced turbofan engines for future tactical aircraft. General Electric Aerospace is developing a competing design called the XA102.

Chris Flynn, vice president of military development programs at Pratt & Whitney’s Gatorworks advanced projects unit, described the new engine as a generational performance leap that simultaneously delivers multiple capabilities previously considered trade-offs.

“You can get range, you can get power and thermal management, you can get survivability, you get more thrust — all at the same time,” Flynn said. “In the past, we’ve had to prioritise [those] just because the technology wasn’t there. But with adaptive technology… you can get a lot of those at the same time.”

The Air Force characterizes adaptive engines as combining the aerodynamic performance of traditional low-bypass fighter engines with the fuel efficiency of high-bypass designs, though specific technical details remain classified.

Both Pratt & Whitney and GE developed similar adaptive engines for the Lockheed Martin F-35 stealth fighter under the earlier Adaptive Engine Transition Program. The Air Force shelved those engines in favor of upgrading the F-35’s existing Pratt & Whitney F135, but advances from that program are now feeding into the next-generation effort.

Digital Revolution in Engine Design

Flynn highlighted one development he considers as significant as the engine technology itself: the transition to fully digital design and development processes.

“You have the real-time ability to go right into the design of the engine,” Flynn explained. “And if you want to look at a particular feature that was a problem on another engine, you can look at it immediately, in real time.”

In his four decades as a propulsion engineer, Flynn said this marks the first time an entire engine has been designed and developed in a digital environment using advanced modeling and simulation.

The shift allows Pratt & Whitney to send digital blueprints and complete engine models to suppliers rather than paper drawings, enabling rapid iteration and reducing costs and production timelines.

“It is probably one of the biggest changes that I have seen in my career,” Flynn said.

Investment Concerns and Chinese Competition

The program follows decades of limited investment in military propulsion technology, with most Western tactical aircraft still powered by engines designed during the Cold War era.

“The challenge that we have is irregular investment,” Flynn noted. “Propulsion engineers aren’t built in a day — you really need to learn the craft.”

Flynn and Steve Russell, his counterpart at GE’s Edison Works, have warned that Washington risks losing its technological edge to China amid industrial espionage and surging Chinese government investment in propulsion manufacturing.

“They are catching up,” Russell said in September. “They’re certainly trying to borrow our technology… like they have in the past.”

Flynn emphasized that maintaining U.S. advantage requires sustained investment not just in manufacturing capacity but in developing new technologies.

“There is very little funding in new technology development,” he said, contrasting it with the steady propulsion investment he experienced earlier in his career.

Investment supports both new designs and improvements to existing powerplants, Flynn noted, specifically mentioning gains in range, aircraft survivability, and power and thermal management. “Bringing the new technologies into [existing engines] make them more capable, lower cost and can bring added capabilities.”

Pratt & Whitney is currently upgrading the F135 to meet growing power and cooling requirements of the F-35 fighter.

Uncertain Deployment Timeline

The Air Force has committed billions to next-generation engine development, but deployment remains uncertain. Multiple sixth-generation platforms are under development, including the Boeing F-47 air superiority fighter and Northrop Grumman B-21 stealth bomber.

Northrop is already flying two B-21 test aircraft, while Boeing expects to fly an F-47 by 2028. However, the new engines are not anticipated before 2030, meaning early sixth-generation aircraft will likely use existing powerplants.

The Navy is also pursuing its own F/A-XX sixth-generation carrier-based fighter with separate propulsion requirements, though that program faces budget uncertainties. Reuters reported the Pentagon is preparing to approve a source selection for the naval fighter, with Boeing and Northrop remaining as finalists after the Navy eliminated Lockheed earlier this year.

Key Takeaways

- Pratt & Whitney began assembling the XA103 prototype engine under the Air Force’s Next Generation Adaptive Propulsion program, competing against General Electric’s XA102 design for sixth-generation fighters.

- The adaptive engine delivers simultaneous improvements in range, thrust, power management and survivability—capabilities that previously required trade-offs due to technological limitations.

- Engineers designed the XA103 entirely in a digital environment for the first time, enabling real-time collaboration with suppliers and reducing development costs and timelines.

- Industry executives warn irregular defense investment and Chinese technological advances threaten U.S. propulsion superiority, despite billions committed to engine development.

- New engines won’t be ready before 2030, meaning early sixth-generation aircraft like the Boeing F-47 and Northrop Grumman B-21 will fly with existing powerplants.